Product Features

1. Durable material: galvanised sheet or stainless steel, with good resistance to acid, alkali and corrosion, can be used in different environments.

2. Practical design: the drop port is designed for easy placement, some adopt anti-theft and anti-handling design; the box has a certain capacity, and some of them can also extend the advertising space.

3. Various functions: ordinary models can meet the basic clothing recycling; intelligent models can have full load prompt, weight sensing, voice interaction, network management and other functions.

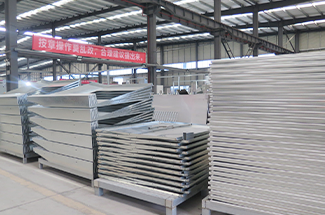

Production process

1. Design: According to the customer’s needs and use of the scene, to determine the size of the clothing recycling bins, appearance style, functional characteristics, and so on. For example, the community may pay more attention to the aesthetics and convenience of placing; public places may need to consider the capacity and anti-theft.

2. Selection of materials: commonly used galvanised sheet, the thickness of 1 – 1.2mm, rust-resistant; there are also stainless steel material, better corrosion resistance but high cost. Part of the intelligent recycling box also need to prepare electronic components.

3. Processing

- Cutting: laser cutting and other equipment, according to the design size of the plate to cut accurately.

- Bending: through the CNC bending machine, the cut sheet will be folded into the required shape of the box.

- Welding: use the welding equipment such as two-polish welding machine to weld the parts into shape, and require the welding joints to be even and burr-free.

- Surface treatment: first anti-rust treatment, and then through the plastic spraying (300 – 900 degrees high temperature so that the plastic powder adsorbed in the box), paint plating and other processes, to enhance the aesthetics and durability of the recycling box.

- Assembly: Installation of locks, drop-in parts, intelligent system (if any), etc. to complete the overall assembly.

Feel free to contact us by email or phone

Post time: May-15-2025